ASPHALT CRUSHING & RECYCLING SYSTEMS

ASPHALT GRANULATORS

EXPERTS IN AGGREGATE RECYCLING SINCE 1964

Cams specialises in creating and producing stationary and portable plants for crushing, screening, and shredding.

CAMS has a wealth of experience in developing and manufacturing cutting-edge solutions for the recycling of various waste materials, including aggregates, asphalt, and rubble. They have been in the industry for over 40 years and are dedicated to delivering innovative products to help improve productivity, efficiency and environmental impact.

The models listed below are particularly suitable for Asphalt granulation and recycling. Please get in touch with our experts to discuss your requirements in more detail and let us find the perfect solution for your business.

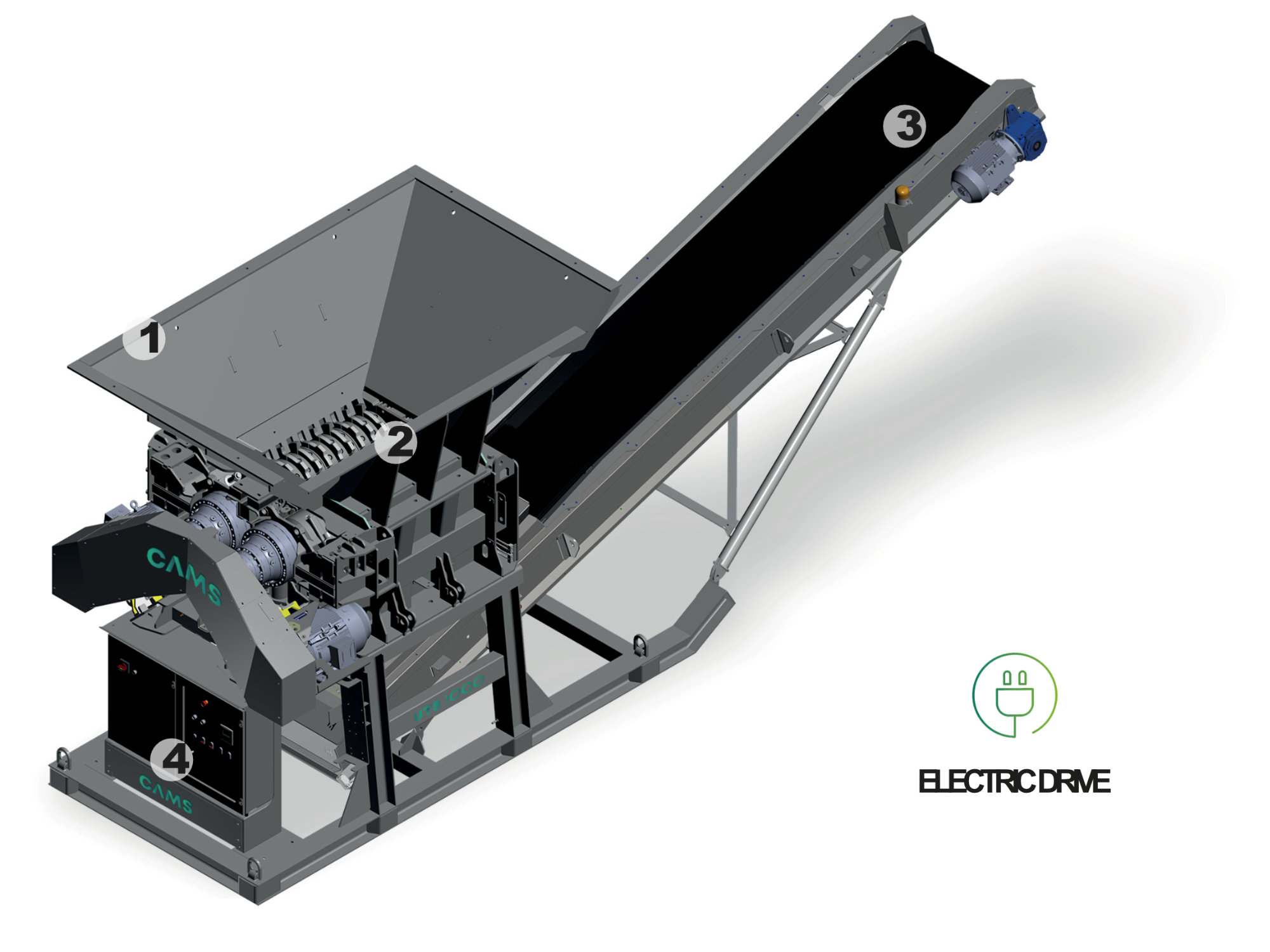

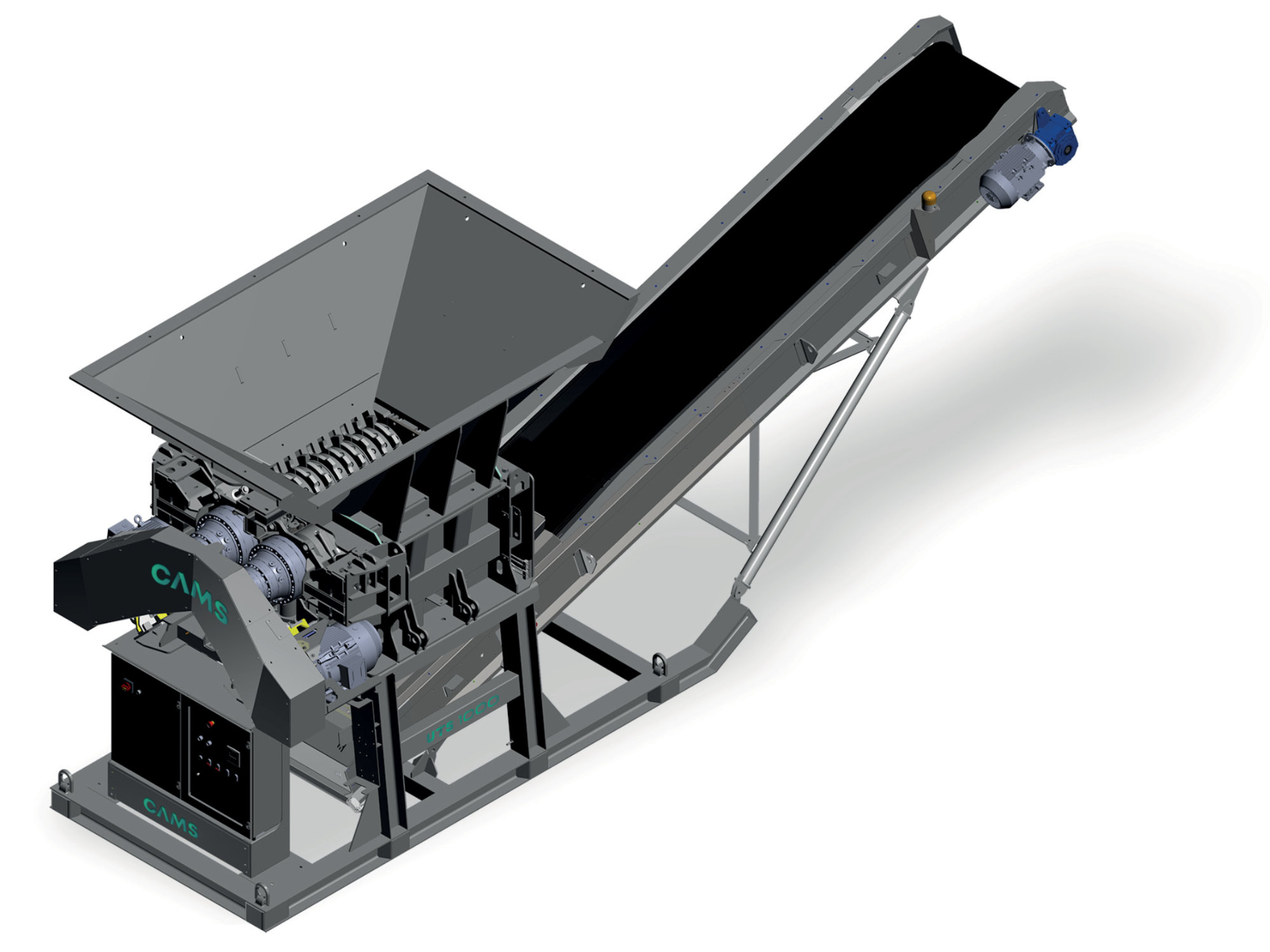

UTS 1000 is a transportable stationary plant for shredding and recycling of aggregates, rubble, asphalt and other materials.

It is able to achieve maximum productivity with minimum consumption; moreover, the slow action of the trees of the shredder guarantees low noise pollution and reduced dust emission

Hopper

Volume: 3.00 m3

Length: 3.00 m

Width: 2.00 m

Shredder

Model: FTR 1000

Surface: mm 1000 x 900

Main conveyor

Width: 800 mm

Lenght: 8 m

Electric drive

Supply: 45 kW

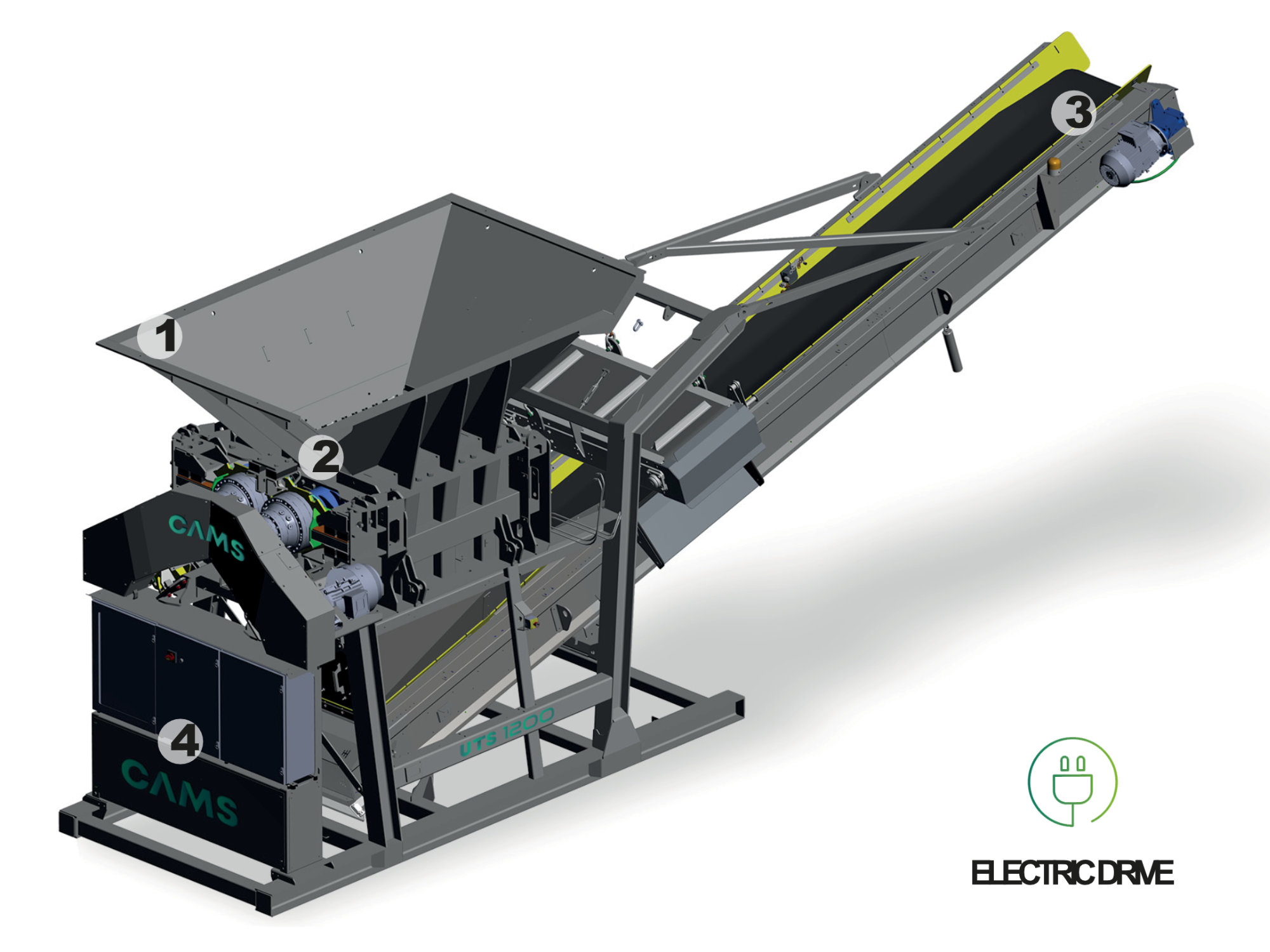

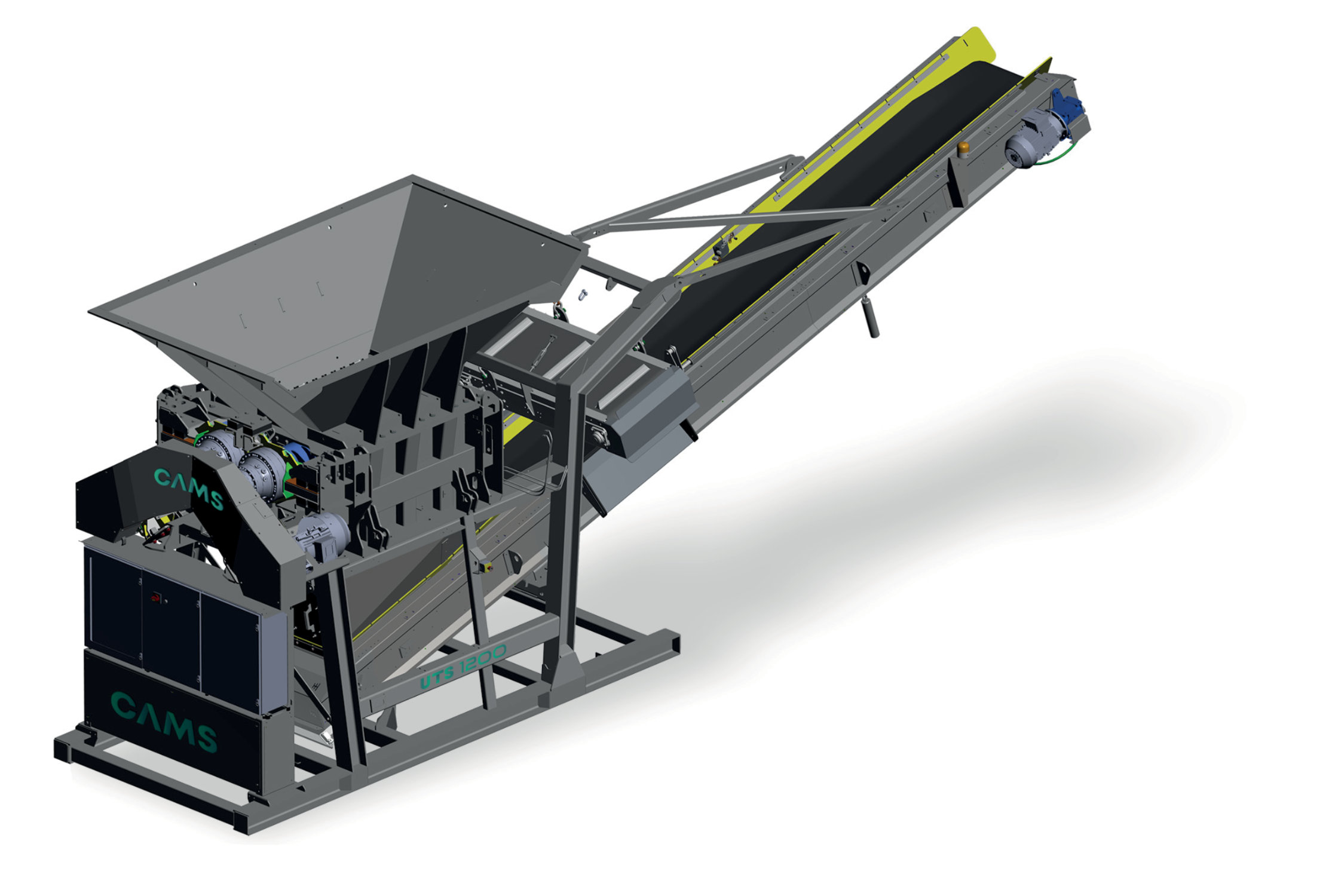

UTS 1200 is a transportable stationary plant for shredding and recycling of aggregates, rubble, asphalt and other materials.

It is able to achieve maximum productivity with minimum consumption; moreover, the slow action of the trees of the shredder guarantees low noise pollution and reduced dust emission

Hopper

Volume: 3.50 m3

Length: 3.20 m

Width: 2.00 m

Shredder

Model: FTR 1200

Surface: mm 1200 x 900

Main conveyor

Width: 800 mm

Lenght: 8 m

Electric drive

Supply: 45 kW

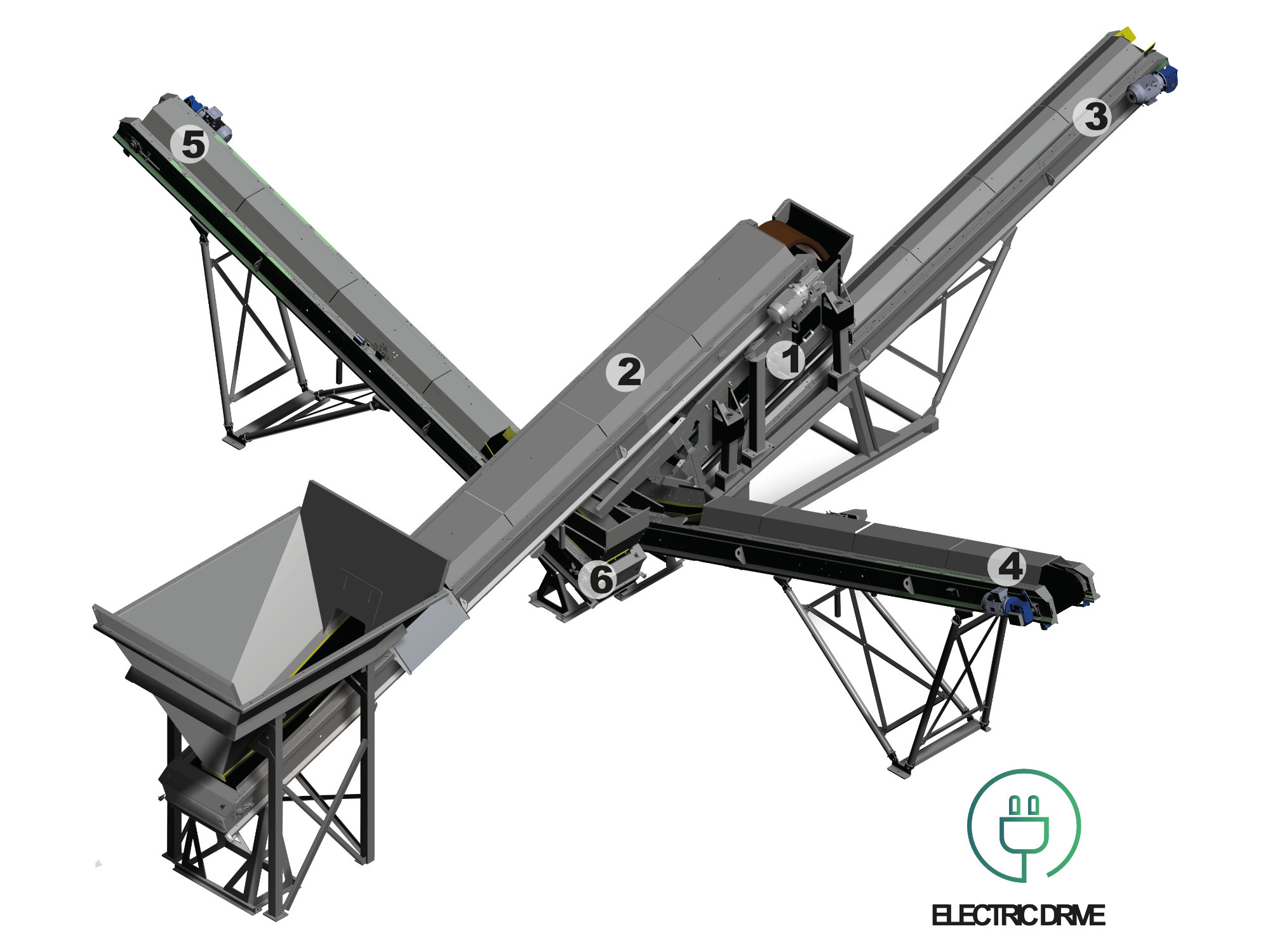

UTS 1200 is a transportable stationary plant for shredding and recycling of aggregates, rubble, asphalt and other materials.

It is able to achieve maximum productivity with minimum consumption; moreover, the slow action of the trees of the shredder guarantees low noise pollution and reduced dust emission

Screen

Model: CVV025

Surface: mm 1000 x 2500

Screen decks: 2

Main conveyor

Width: mm 800

Finesize conveyor

Width: 800 mm

Midsize conveyor

Width: mm 500

Oversize conveyor

Width: mm 500

Electric drive

Supply: 25 kW

FEATURES

OPTIONS

- Ability to process wet materials

- High wear resistance

- Low emissions and acoustic pollution

- Feeding hopper

- GPS

- Belt scale

LEARN MORE ABOUT OUR SERVICES

PARTS & SERVICE

- Technical Support & Advice

- Product Selection Guidance

- Service & Onsite Support

- Planned Maintenance

- Replacement Parts

STEEL FABRICATION

- Custom Fabrication Services

- 25 Years Industry Experience

- Highly Skilled Engineers

- Specialist in Welding, Cutting & Machining

- ISO 9001:2015 Accreditation

PROCESS HEATING

- A K Waugh Process Heaters

- 82 years experience

- Immersion, Outflow, Line Heaters

- For Oils, Chemicals, Water

- ATEX/GOST Hazardous Area Equipment